Custom Wall Panel Solutions

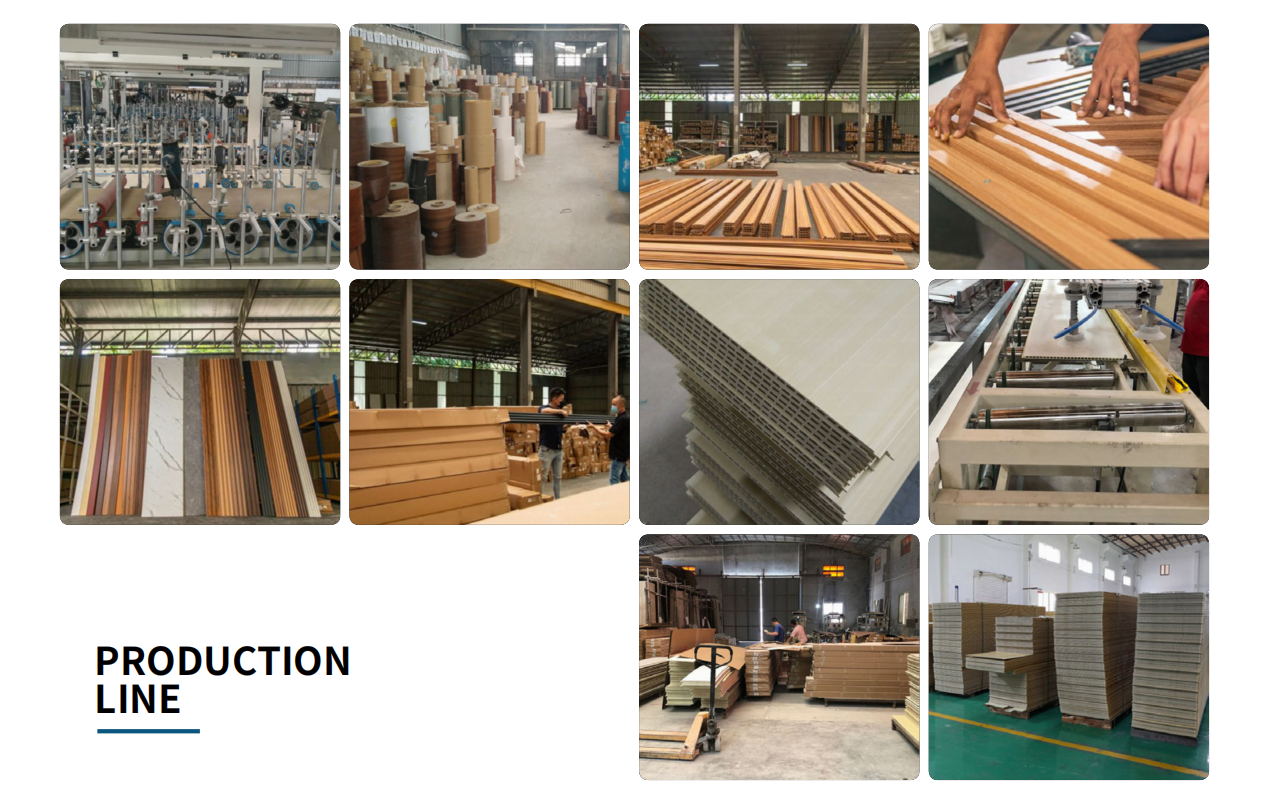

Elevate your projects with Longhan’s truly sustainable wall solutions. We deliver more than just panels—we provide complete peace of mind. Our ENF-certified products (0.011mg/m³ formaldehyde) ensure immediate occupancy, eliminating harmful emissions concerns. With extensive standard sizes, perfect color-matching components, and rapid installation systems, we significantly reduce your project timelines while offering unlimited design possibilities. Trust our integrated manufacturing and rigorous quality control to bring your vision to life without compromise. Contact our specialists today to request your complimentary sample kit and discover the Longhan difference.

Golden Arch Wall Panel

Solid Wood Grating Wall Panels

Bamboo Wood Fiber Grating Wall Panel

Custom Trim Solutions

We specialize in creating tailored trim components that integrate perfectly with your wall panel systems. Our engineering team works directly with you to develop custom profiles, exact color matches, and specialized finishes for any project specification. From unique geometric shapes to brand-specific requirements, we transform your design concepts into precision-manufactured reality.

Our custom solutions eliminate installation challenges and ensure flawless transitions throughout your space. With factory-direct manufacturing and rigorous quality control, we guarantee consistent results while meeting your project timeline and budget parameters. Contact our technical team to discuss your specific trim requirements and receive custom samples.

Why Choose Chinalonghan ?

Experience the benefits of smooth moving

Environmental Safety

Achieve absolute peace of mind with our ENF-certified panels (0.011mg/m³ formaldehyde), enabling immediate occupancy and ensuring complete well-being for all end-users.

Streamlined Installation

Accelerate your project timelines with our quick-install systems and comprehensive color-matching components, effectively reducing labor costs and installation cycles by over 50%.

Superior Climate Resilience

Ensure long-term project integrity with panels engineered for exceptional stability, significantly reducing risks of deformation and aging even in varying environmental conditions.

Complete Customization Solutions

Access 150+ standard sizes and full custom capabilities with perfectly matched components, providing designers unlimited flexibility while minimizing material waste.

The Ultimate Guide

How to Import Custom Wall Panel From China

Table of Contents

Importing custom wall panels from China has never been more accessible or rewarding. Whether you’re outfitting a high-end residential project with 3D textured panels, specifying acoustic solutions for commercial spaces, or sourcing modular metal systems for industrial builds, Chinese manufacturers deliver unparalleled customization at 30-50% lower costs than domestic alternatives. In 2025, with streamlined digital platforms, third-party inspections, and mature logistics networks, even small importers can achieve factory-direct pricing without the traditional headaches.

This blog distills proven strategies from veteran sourcing agents, factory audits, and real importer experiences. Follow these steps to secure premium custom wall panels—WPC, SPC, PVC, aluminum composite, or bamboo-fiber—while minimizing risks and maximizing profits.

Here are stunning examples of what Chinese factories can produce:

Why China Remains the #1 Source for Custom Wall Panels

- Cost Advantage: A 20ft container of SPC wall panels (≈1,000 m²) typically costs $8,000–$12,000 EXW, versus $25,000+ domestically.

- Customization Depth: Factories offer OEM tooling for unique textures, perforations, curvatures, and integrated LED channels.

- Scale & Speed: Facilities producing 5,000+ m² weekly can deliver rush orders in 4–6 weeks.

- Quality Maturity: ISO 9001, CE, ASTM, and EN certifications are standard among reputable suppliers.

Step-by-Step Import Process (Visual Guide)

![How to Import from China to the US in 6 Steps [2024]](https://fitsmallbusiness.com/wp-content/uploads/2024/04/FSB_ImportFromChina_24_KD_rnd1-1024x797.png)

Step 1: Define Your Exact Specifications (1–2 weeks)

Success begins with crystal-clear requirements:

- Material (WPC, SPC, PVC, aluminum honeycomb, PU stone, etc.)

- Dimensions (standard 2.8m × 0.6m or custom)

- Finish (wood grain, marble, matte, high-gloss, PVDF coating)

- Performance (fire rating A/B, waterproof IP68, acoustic NRC 0.8+)

- Quantity & packaging (flat-pack vs assembled)

- Certifications needed for your market

Create a one-page tech pack with CAD drawings, color codes (RAL/Pantone), and test standards. This prevents 90% of quality disputes.

Step 2: Source & Shortlist Suppliers (2–4 weeks)

Best Platforms in 2025

- Alibaba.com – Use “Trade Assurance” + “Verified Supplier” filters

- 1688.com – Domestic prices 15–30% lower; requires agent or translator

- Made-in-China.com – Strong for building materials

- GlobalSources.com – Premium audited factories

Search terms: “OEM SPC wall panel factory”, “custom 3D WPC wall panel manufacturer”, “A2 fire-rated aluminum composite panel”

Target factories in:

- Hubei (SPC/WPC hub)

- Guangdong (metal composites)

- Shandong (PVC/acrylic)

Aim for 15–20 RFQs. Red flags: no factory photos, refusal to share business license, prices 40% below market.

Step 3: Verify Suppliers Like a Pro (1–3 weeks)

Never skip this step—80% of horror stories trace back to unverified suppliers.

Verification Checklist

- Business license (verify on gsxt.gov.cn)

- Export license & VAT registration

- ISO 9001/14001 certificates

- Third-party audit reports (SGS, Bureau Veritas)

- Factory video tour (request WeChat live walk-through)

- Client references (ask for U.S./EU contacts)

- Onsite visit or hire inspector ($268–$388/day)

Pro tip: Use paid services like Alibaba’s “Inspection Service” or independent agents (3–8% commission).

Step 4: Order Samples & Lab Testing (3–5 weeks)

Always order golden samples ($150–$400 each) before production.

Test for:

- Color fastness (UV exposure)

- Formaldehyde emission (E0/E1)

- Fire rating (ASTM E84, EN 13501)

- Impact resistance

- Dimensional stability

Chinese labs charge $200–$500; results in 7–10 days.

Step 5: Negotiate Contract & Payment Terms

Ironclad Contract Clauses

- Detailed spec sheet attached

- Quality standards & tolerance (±0.5mm thickness)

- Inspection rights (pre-shipment mandatory)

- Penalty for defects (>2% rejection = free replacement)

- IP ownership of custom molds

Safest Payment Structure

- 30% deposit (T/T)

- 70% against BL copy AFTER passing inspection

- Use Alibaba Trade Assurance or Letter of Credit for orders >$20,000

Avoid Western Union or personal accounts—scam indicator #1.

Step 6: Production Monitoring & Quality Control (4–8 weeks)

Hire third-party inspection at three stages:

- Raw material check

- Mid-production (50% complete)

- Pre-shipment (100% complete + packing)

Cost: $198–$318 per man-day. Worth every penny—catches issues like delamination, color variance, or wrong core density.

Step 7: Shipping & Logistics

Container Loading Example (20ft)

- SPC panels: ~1,000 m²

- WPC panels: ~800 m²

- Weight limit: 21–23 tons

Freight Rates Nov 2025

- Shanghai → Los Angeles: $2,800–$3,500

- Ningbo → Rotterdam: $3,200–$4,000

- Shenzhen → Sydney: $2,900–$3,600

Use freight forwarders like Flexport, ShipBob, or local Chinese agents. Opt for CIF terms to shift risk.

Protect panels with:

- Corner protectors

- VCI anti-corrosion film

- Wooden crating for high-end finishes

Step 8: Customs Clearance & Duties

HS Codes & Duties (2025)

- PVC panels: 3925.90 → USA 3.5% + 25% Section 301 = 28.5%

- WPC panels: 4411.92 → USA 8% base + 25% = 33%

- Aluminum composite: 7606.12 → USA 6% + 25% = 31%

- EU rates generally 0–4.7% (no Section 301)

Documents Required

- Commercial invoice

- Packing list

- Bill of lading

- Certificate of origin (Form A for GSP if applicable)

- Third-party test reports

Hire a customs broker ($150–$300) to avoid delays.

Landed Cost Breakdown Example (20ft container SPC panels)

| Item | Cost (USD) |

|---|---|

| EXW price (1,000 m²) | 10,500 |

| Inland transport to port | 400 |

| Export clearance | 150 |

| Ocean freight (CIF LA) | 3,200 |

| Marine insurance (0.3%) | 42 |

| U.S. duties (28.5%) | 3,191 |

| Customs broker | 250 |

| Port fees & trucking | 800 |

| Total Landed Cost | $18,533 |

| Cost per m² | $18.53 |

- MOQ Trap: Factories quote low prices for 10,000 m² but charge $2,000+ for tooling on smaller runs. Solution: Negotiate shared mold costs.

- Color Drift: Lighting differences cause mismatches. Solution: Use Datacolor spectrophotometer calibration.

- Hidden Tariffs: USA Section 301 tariffs still apply in 2025. Solution: Route via Vietnam/Malaysia for transshipment (legal with proper COO).

- Moisture Damage: Panels warp in humid containers. Solution: Demand silica gel packs + humidity indicators.

- Supplier Ghosting: After deposit, communication stops. Solution: Never pay >30% upfront without Trade Assurance.

Final Tips for 2025 Success

- Start small: First order 1–2 containers max.

- Build relationships: Visit Canton Fair Phase 1 (April/May) or attend factory tours.

- Use sourcing agents for 1688.com to access 20–35% lower prices.

- Consider bonded warehouse storage to defer duties.

Importing custom wall panels from China in 2025 is straightforward when you follow this proven framework. Thousands of contractors now enjoy 40%+ margins by sourcing directly. Ready to transform your next project? Start with a detailed RFQ today—your perfect panels are just 8–10 weeks away